Fibre quality: the strength of our reputation

Despite our relatively small crop, Australian exports still make up over 10 per cent of the medium/high grade cotton volume in the export market.

The quality of Australian cotton has improved over the last two decades and has earned a very good reputation amongst spinners for its good spinning ability and low contamination.

Nearly all of Australia’s cotton lint is exported for high-quality end use in mills in Southeast Asia. It is used primarily for producing high-quality fine to medium count ring spun yarns for use in the woven and knitted apparel sectors.

What do you need to know?

The price received for cotton is dependent on the quality of each bale of cotton.

A sample should be extracted from each side of a bale preferably at the gin but in some extenuating circumstances at the warehouse. The sample should be at least 120 mm wide, 220 mm long and 140 mm high with a weight of about 200 grams. This size is especially important for colour and trash measurement where the sample window must be fully covered by the specimen in order to obtain an accurate measurement.

Cotton prices are quoted for ‘base grade’, with the base grade referring to the grade of cotton that is used by cotton merchants as a basis for contracts, premiums, and discounts.

Currently the base grade for Australian cotton is Colour 31 (Middling) with Leaf 3, length 36 32nds, micronaire G5 (3.5 to 4.9) and strength 28 g/tex with premiums and discounts applied for higher and lower grades, respectively.

The key characteristics:

Colour: The colour of commercially grown cotton varies from white to creamy to yellow and is mainly determined by the cultivar and growing conditions, such as temperature, rainfall, frost, insects and fungi. Staining, through contact with soil, grass or other parts of the cotton plant, moisture during harvest and ageing during prolonged storage can also deteriorate the colour of cotton.

Cotton colour has little effect on the processing performance and quality during spinning and fabric manufacture, provided that the colour has not been compromised by microbial decay, which may also have an effect on the length and strength of the fibre. However, as textile mills process cottons of different grades and origins, the control of fibre colour is essential, as colour differences may affect dyeing and finishing results. The process of bleaching, prior to dyeing, is often able to reduce, or even eliminate, colour differences present in the raw cotton.

Cotton is still largely bought and sold on the basis of a cotton classer’s subjective assessment of grade relative to a prepared physical sample of the said grade. In awarding a classing grade, the classer will assess the sample’s colour, visible trash (leaf grade) and preparation (degree of smoothness or roughness of the cotton sample) relative to the appearance of a physical grade. The physical sample grades were established by the United States Department of Agriculture (USDA) in the early 1900s to eliminate price differences between markets, provide a means of settling disputes and to make the grower more aware of the value of their product. Nowadays, USDA physical grade boxes and the qualities they represent are globally accepted and routinely used to trade cotton worldwide. The only exception being that some cotton is sold on physical grades and shipper types represented by actual samples, which are used for reference purposes against the shipped cotton.

The colour grading of Upland cotton considers both major and minor differences in colour. Major colour differences occur between the five classes of ‘white’, ‘light spotted’, ‘spotted’, ‘tinged’ and ‘yellow’ stained cotton, chiefly due to increasing degrees of yellowness across the five classes. Within each of these classes the reflectance or whiteness of the fibre is assessed across another eight levels from ‘Good Middling’ through to ‘Below Grade’. There are currently 25 official physical colour grades for Upland cotton and five grades for below grade colour- see Table.

Official colour grades applied to Upland cotton:

Designation | Abb | White | Light Spotted | Spotted | Tinged | Yellow Stained |

Good Middling | GM | 11 | 12 | 13 | - | - |

Strict Middling | SM | 21 | 22 | 23 | 24 | 25 |

Middling* | M | 31 | 32 | 33 | 34 | 35 |

Strict Low Middling | SLM | 41 | 42 | 43 | 44 | - |

Low Middling | LM | 51 | 52 | 53 | 54 | - |

Strict Good Ordinary | SGO | 61 | 62 | 63 | - | - |

Good Ordinary | GO | 71 | - | - | - | - |

Below Grade | BG | 81 | 82 | 83 | 84 | 85 |

* Base grade

Due to the subjective nature and inconsistency of manual classing, the need for objective measurement led the USDA in the 1970s to consider the feasibility of colour measurement by instrument. With the development of colorimeter technology and then the incorporation of colorimeters into HVI lines, the classification of colour by instrumentation became feasible. Objective measurement of cotton fibre colour is defined in terms of the Nickerson-Hunter model, which describe colour in terms of greyness or reflectance (Rd) and yellowness (+b).

Together with refinements in instrumentation and calibration techniques has led to USDA’s adoption of HVI measured colour grades for all U.S. cotton since the early 2000s, with the world industry playing catch up since that time with Australia in the process of transitioning.

Leaf: Also known as ‘trash’ is a measure of the amount of leaf material remaining in the cotton sample. The amount of trash present in a bale of cotton is affected by the variety, harvesting method and conditions, and whist the gin removes the majority of trash, some will remain in the sample which will be removed during the spinning process resulting in a reduction in lint yield and increased cost. Hence, cotton with high levels of trash attracts a discount. Leaf grades range from 1 (lowest amount of trash) to 7 (highest amount of trash).

Extraneous Matter

Extraneous matter is determined by the human classer and is defined as any substance in a cotton sample that is not cotton fibre or leaf material. When extraneous matter is prevalent in a sample, a notation will be made by the classer in the classification data for that cotton sample. In essence extraneous matter are contaminants including bark, grass, seed-coat fragments, spindle twist, dust, oil, and plastic which will be touched on in the contamination and seed-coat fragment sections.

Staple length: Fibre length will determine the spinning system to be used (i.e., ring, rotor, or air-jet), the specifications in terms of drafting roller distances, yarn count and twist, as well as processing speeds. Excessive fibre length variation and an associated increase in short fibre content (fibres shorter than 12.7 mm or 0.5 inch) will result in increased waste and adversely affect processing performance (i.e., ends down, fly, comber noil, etc.) and a deterioration in yarn quality, in terms of yarn strength, hairiness, and evenness, specifically ring-spun, and subsequently fabric quality, including handle and lustre.

Fibre lengths of Upland cotton range from as low as 15 mm (0.59 inch) to 32 mm (1.26 inch) with ELS cotton ranging from 32 mm (1.26 inch) to 51 mm (2.01 inch).

Fibre length is largely a genetic trait and varies considerably across different cotton species and varieties. Length and length distribution are also affected by agronomic and environmental factors during fibre development, and mechanical harvesting and ginning. Gin damage to fibre length is known to be dependent upon variety, seed cotton moisture, trash content, moisture during ginning and field exposure.

It is also worth mentioning, that fibre length distribution presents a serious challenge, in most other natural fibres, such as wool and mohair, but seldom in man-made fibres.

Upland length conversation chart:

Length | Length | Length | Length |

|---|---|---|---|

24 | 0.79 & shorter | 36* | 1.11 – 1.13 |

26 | 0.80 – 0.85 | 37 | 1.14 – 1.17 |

28 | 0.86 – 0.89 | 38 | 1.18 – 1.20 |

29 | 0.90 – 0.92 | 39 | 1.21 – 1.23 |

30 | 0.93 – 0.95 | 40 | 1.24 – 1.26 |

31 | 0.96 – 0.98 | 41 | 1.27 – 1.29 |

32 | 0.99 – 1.01 | 42 | 1.30 – 1.32 |

33 | 1.02 – 1.04 | 43 | 1.33 – 1.35 |

34 | 1.05 – 1.07 | 44 & + | 1.36 & + |

35 | 1.08 – 1.10 |

*Base grade

Micronaire: Micronaire, a combination of fineness and maturity, has a substantial influence on processing performance, Excessive micronaire variation can lead to streakiness or barré due to differences in dye absorbency and retention and hence the levels within a laydown or blend should not vary excessively

Micronaire is measured by placing lint in a chamber, compressing it to a set volume and subjecting it to a set pressure. The micronaire result measured in this way is in fact a function of both fibre maturity and fineness (linear density). As the reading is an approximate guide to fibre thickness the trade use the following micronaire ranges to describe samples:

Micronaire is one of the most challenging fibre quality parameters to manage as it is subject to penalties for being either too high or too low. Table 3 provides information of worldwide classification and description for interpreting micronaire values. The table shows that the base grade falls in the range of 3.5 to 4.9 with the premium range 3.7 to 4.2. Any cotton with micronaire below base grade will be severely discounted as they are considered to be immature whereas cotton above base grade are not as severely discounted as they can be used to produce lower quality coarse yarns.

≥ 5.3 | G7 |

5.0 – 5.2 | G6 |

3.5 – 4.9* | G5 |

3.3 – 3.4 | G4 |

3.0 – 3.2 | G3 |

2.7 – 2.9 | G2 |

2.5 – 2.6 | G1 |

≤ 2.4 | G0 |

* Base grade

Strength: The ability of cotton to withstand tensile force is fundamentally important in the processing of cotton. Fibre strength is highly dependent on the variety, although environmental conditions can have a small effect. Rain grown cotton strength is usually not adversely affected by growing conditions. Fibre strength is measured by clamping a bundle of fibres between a pair of jaws and increasing the separation force until the bundle breaks.

Most Australian varieties are of high strength, which is expressed in terms of grams force per tex with the following classifications:

Descriptive Designation | Strength (grams per tex) |

Weak | 23.0 & below |

Intermediate | 24.0 – 25.0 |

Average | 26.0 – 28.0 |

Strong | 29.0 – 30.0 |

Very strong | 31.0 & above |

Contamination: Australian cotton is recognised as one of the least contaminated cottons in the world and receives a premium - so any contaminants lower the value of the product and can potentially damage our reputation. Contaminants can either be natural (rocks, wood, leaf, bracts, bark, green leaf, burrs, and honeydew), or man-made (torn cotton tarps and plastic wrap, twine, oil, hydraulic oil, grease, pieces of metal and equipment, food wrappers, drink bottles, mobile phones, and cleaning rags). In Australia, the biggest issue is plastic, since the majority of the crop is harvested with harvesters that produce round modules which are covered with plastic wrap.

Stickiness: Cotton stickiness, when it occurs, can present a major problem, in terms of textile processing performance and cost and product quality. If a country gains a reputation for stickiness, they have difficulty selling their cotton, and incur large discounts. The most common and problematic causes of stickiness are those due to excess sugars related to insect secretions, notably aphids and whitefly and is described as honeydew and responsible for some 80 to 90 percent of stickiness problems. In addition, a black sooty mould can also grow on honeydew, darkening the lint and adversely affecting grade.

Other important quality characteristics

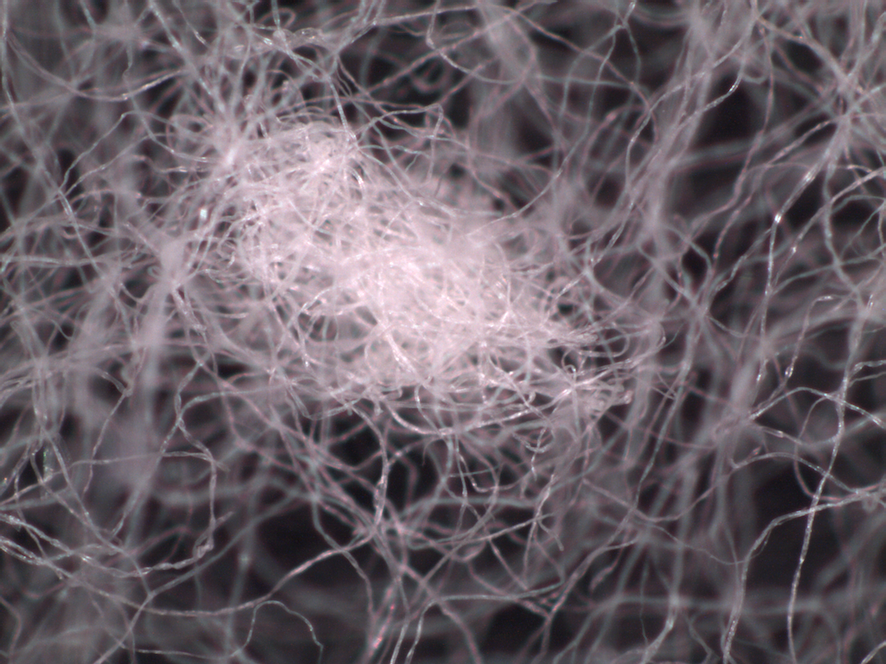

Neps: Neps are defined as an entanglement of two or more fibres, creating a small knot (pictured below). Neps are primarily caused by immature fibres which affect the appearance of cotton yarns and subsequently the fabric made from them. Neps are usually associated with lower yarn strength, higher ends down in spinning, less uniform yarn, causing a loss in spinning efficiency as well as resulting in stoppages defects during fabric manufacture. The appearance of dyed or printed fabrics is also negatively influenced by the presence of neps, as immature fibres absorb less dye and appear as white spots or flecks on finished fabrics.

Seed coat fragments: Seed-coat fragments (pictured below) appear during the ginning process when the lint is removed from the seed. The fibre is not cleanly removed from the seed coat and the fibre will carry a slight fragment of seed-coat. This is problematic as seed-coat fragments are very difficult to remove and can cause yarn faults or breaks, reducing the overall quality of the final product as they appear as brown/dark spots or flecks on finished fabrics.

So, what should you do on your farm?

Fortunately, most crop management factors which increase/optimise yield will also increase/optimise fibre quality. Below are a few decisions which could affect your fibre quality:

- Select an appropriate variety for your region according to recommendations from CSD.

- Choose the optimal sowing date for your area to maximise yield and fibre quality.

- Effective control of weeds to minimise contamination, staining and reduced harvest efficiency.

- Meeting the nutritional requirements of the crop as nutritional excess and deficiencies can have a significant effect on fibre quality.

- Implement good IPM strategies to avoid insect damage and avoid unnecessary pesticide applications.

- Avoid aphid and whitefly infestations to avoid sticky cotton.

- Optimise the timing of cut-out to minimise harvest of immature bolls.

- Apply good defoliation (product, rate, and time) and a timely harvest.

- Implement good farm hygiene practices to avoid contamination.

- Ensure harvesters (both spindle and strippers) are regularly maintained and correctly set up.

- Avoid harvesting seed cotton with moisture content > 12 per cent.

- Ensure module wrap/tarpaulins are intact and not damaged.

Visit the myBMP fibre quality module for more information

Where should you go for more information?

Technical lead:

René van der Sluijs – Technical Lead Fibre Quality

P: 0408 885 211

E: renevandersluijs@gmail.com

Publications:

- Australian Cotton Production Manual

- FIBREpak

- CottonInfo Defoliation: End of Season Management booklet

- CottonInfo defoliation preparation fact sheet

- CottonInfo contamination in cotton fact sheet

- CottonInfo turn out fact sheet

- Cotton Incorporated's Classification of Cotton classing booklet

- Cotton Incorporated's Prevention of plastic contamination when handling cotton modules booklet

- CSIRO's Contamination and its significance to the Australian cotton industry booklet

- John Deere TamaWrap (wrap for round modules) booklet (includes best practice)

- CottonInfo podcasts on improving fibre quality at picking